The main features in brief:

- Extended mould diagnosis

- For 24 to 240 zones in steps of 8

- 230V / 16A per zone

- Industrial PC with 15” touch panel

- Software updates per download

The main features in brief:

Up to 240 zones on four wheels with maximum operating comfort: Clear touch panel and maximum data compatibility – this “control cabinet” is where it’s at! The JETmaster TP, the floor-mounted device from our systematic TP series, combines all the requirements for optimum process reliability and ease of use in one device. Once connected, all moulds are immediately operational again without the need for a restart. Comfortable: the control via industrial PC with large touch panel. Profitable: Maximum-sized external cooling elements ensure that the device remains maintenance- and wear-free.

JETmaster TP

Housing:

Aluminium, colour RAL 5010 gentian blue, special colours available upon request

Dimensions:

See table “equipment designs”

Temperature control:

Microprocessor controlled multi-loop controller with automatic computation of the control parameters for each zone

Operation / Visualisation:

Industrial PC with 15” touch panel

Sensor input:

Thermocouple Fe/CuNi, switchable to Ni/CrNi with internal thermocouple reference junction

Temperature range:

0-500 °C, switchable to 32-932 °F

Calibration accuracy:

≤ 0.25%

Heating outputs:

max. 230 VAC/16 A =3680 W per zone, trouble-free switching algorithm, secured by super-fast-acting (FF) safety fuses 16A, 6.3 x 32mm

Alarm output:

Potential-free alarm contact, max. load up to 250VAC / 2A (can be inverted)

Safety shutdown:

Load shedding in the case of failed Triac (short circuit)

Reduction / Boost:

Can be switched both manually and externally via the 24 VDC control circuit

Mould connection:

According to customer specification

Power supply:

400 VAC +10…-10%, 50…60Hz, 3P / N / PE, other voltages upon request

Power supply:

CEE 32 A, CEE 63 A, CEE 125 A, Multiple feed, connector

Interfaces:

Interfaces: 1x USB-external, 1x Ethernet, OPC/UA,

optional RS232, RS485, TTY

Control fuse:

Safety fuse MT 6.3 A, 5 x 20 mm

Ambient temperature:

Operation 0…+55 °C, storage -30…+70 °C

Climatic application class:

According to DIN 40 040, relative humidity 75% in the annual average, no condensation

Protective system:

IP20

Protection class:

I

JETmaster TP

Industrial PC with 15“ touch panel, optionally with offset screen. The JETmaster TP is fanless and maintenance-free.

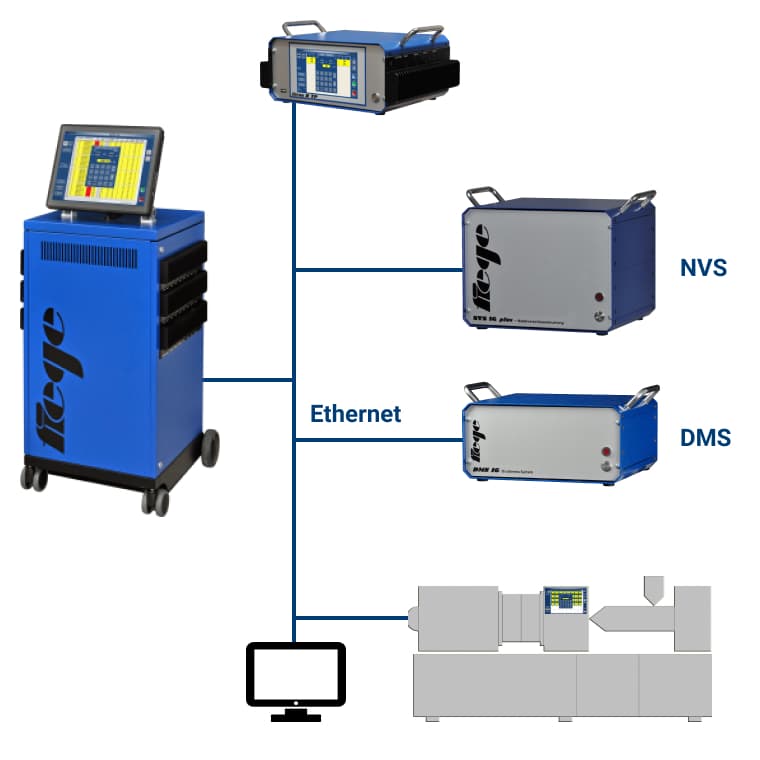

All device data and mould settings can be centrally stored and managed via the Ethernet connection. We will manufacture the mould and network connections according to your individual company standards.

All device data and mould settings can be centrally stored and managed via the Ethernet connection. Furthermore, additional devices such as needle valve-control NVS and pressure measuring system DMS are linked with the devices via the Ethernet connection. These then perform the operation and visualisation. Various injection moulding machines can be connected via conventional data interfaces or via the Ethernet so that operation and visualisation occurs on the machine’s screen.

JETmaster TP

| Type | Zones | Item No. | Size (mm) W x H x D |

|---|---|---|---|

| JETmaster TP compact | 24 tot 48 | 1810-xxxx-48* | 480 x 1360 x 470 |

| JETmaster TP | 24 to 96 | 1610-xxxx-96* | 480 x 1360 x 470 |

| JETmaster TP | 104 to 144 | 1610-xxxx-144* | 480 x 1590 x 470 |

| JETmaster TP | 152 to 192 | 1610-xxxx-192* | 480 x 1800 x 470 |

| JETmaster TP | 200 to 240 | 1610-xxxx-240* | special |

Special versions on request

xxxx = will be replaced by a custom version number when the order is placed.

Subject to modifications.

Downloads

Contact

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Turnstile. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information