The main features in brief:

- Optimise your operating processes

- Compatible with Fiege hot runner controllers

- Increases production process reliability

The main features in brief:

Complement your hot runner control technology with practical extras, simplifying your processes and increasing the reliability of your manufacturing. We are continuously expanding our product range – come back regularly and learn more about our innovations!

Accessories

To connect to the alarm contact of hot runner controllers of the TP series. Provides an acoustic and visual signal for process reliability during production in the case of an alarm, e.g. in case of sensor breakage, leakage and temperature outside of the alarm band.

Item No. 700-02-00

For use in moulds which are insulated and stored on a testing area for repair purposes (usually on wooden beams) and have no or inadequate grounding.

Item No. 890-01-10

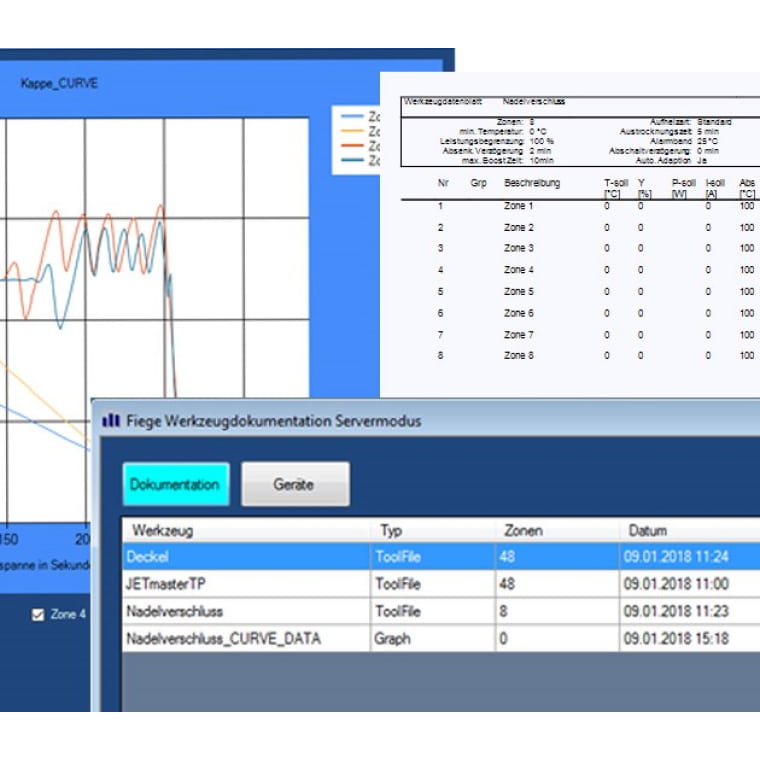

Software with mould-server functionality – to manage, display and print moulds, mould diagnoses and temperature curves, responsive from all connected TP hot runner controllers within the company network.

Item No. 600-01-01

Consisting of an aluminium profile frame with two shelves and cable holders on lockable twin casters

Dimensions (L x W x H): 410x635x900mm with cable holder

Load-bearing capacity: max. 30kg per shelf

Weight: 14.1 kg

Item No. 700-00-03

Can be inserted from both sides

Item No. 920-11-61

With master key, current download links, free version “mould documentation” and operating manual for fitron TP and JETmaster TP

Item No. 913-99-01

For recessed screen incl. VESA 75/100 connection plate, rotary flange for 30mm pipe diameter and wall profile

Item no.: 905-21-26

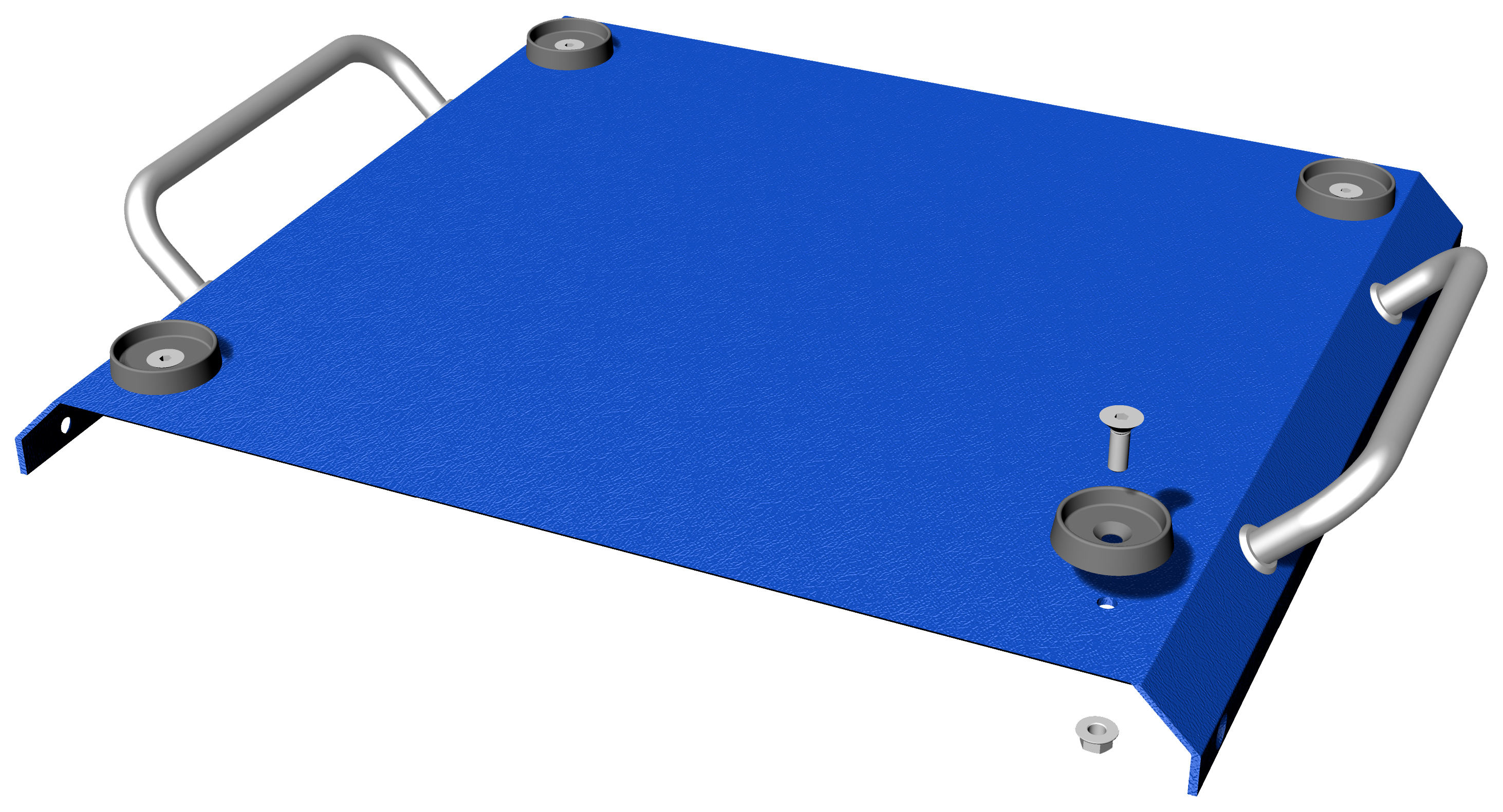

Assembly kit as a slide stop for stacked devices

Consisting of: 4 plastic plates, screws and drilling template

Item no.: 920-12-05

RFID reader for fast mould change and short set-up times. Hold the reader onto the mould and the corresponding mould data set is loaded automatically.

One mould TAG is required per mould.

Art.no. 700-06-00 (reader)

Art.no. 700-06-01 (mould TAG)

Download

Contact